Plant Environment Optimization

It wasn't enough for the hydroponic system to be fully automated. It also needed to be fully optimized. It turns out there is more than just light or water and there are several factors that affect plant growth

Major factors effecting plant growth:

PH

Nutrient Level

Water Temperature

Water Oxygen Level

Photosynthetically Active Radiation (PAR)

Air Temperature

Vapor Pressure Deficit

CO2

Genetics

PH

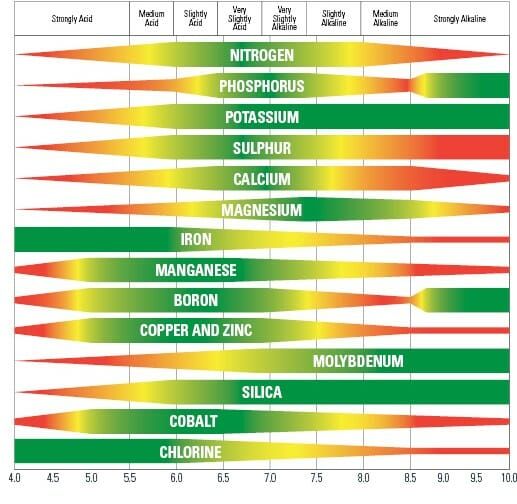

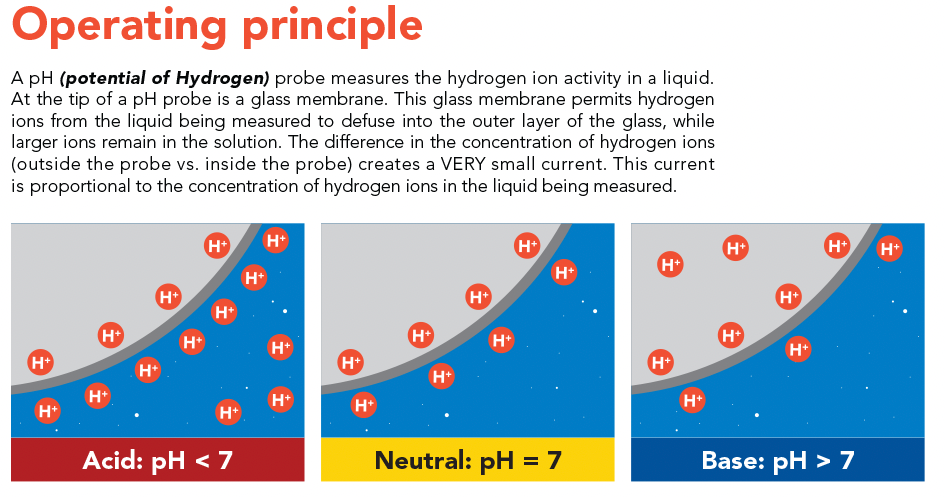

PH or Potential Hydrogen is the level of hydrogen ion activity in a liquid and is represented by a scale that specifies the acidity or basicity of a solution. The PH of the solution determines how much and what nutrients a plant can absorb

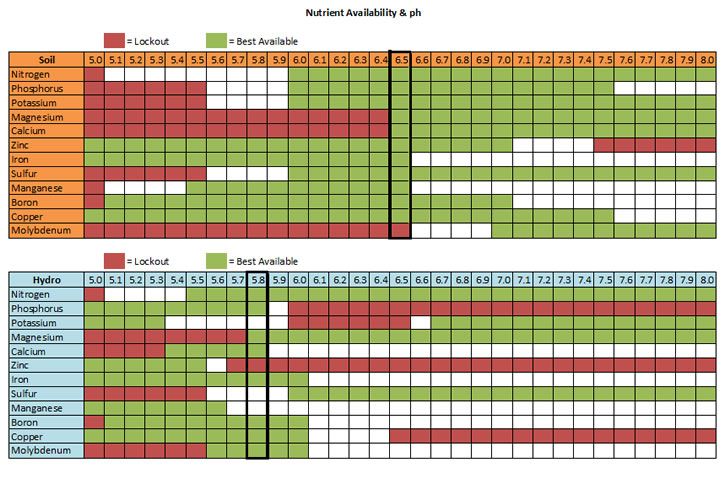

If the PH is too low/high it will cause nutrient lockout preventing the plant from absorbing certain nutrients. The growth medium changes how a plant absorbs nutrient so the optimal PH will be different if using a soil vs hydroponic setup

Different plants needs different levels of nutrients.

The level of nutrients each plant absorbs be controlled through the PH. Because of this plants will have a different optimal PH levels

In soil you generally change the PH by adding something such as wood ashes or coffee grounds which will raise or lower the PH respectively. In a hydroponic system where the amount of organic material needs to be limited, phosphoric acid (PH Down) and potassium hydroxide (PH Up) are used as buffering solutions

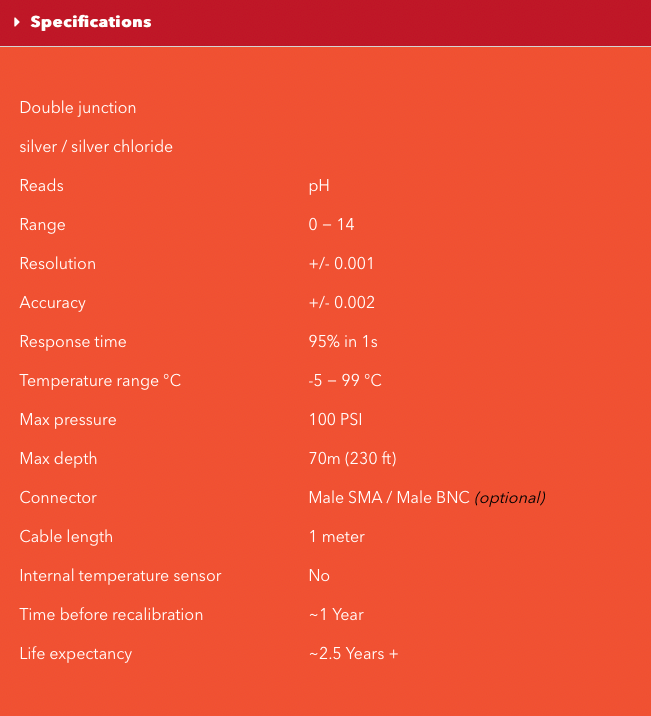

In my setup, I use a continuous monitor PH probe connected to a Raspberry PI. Hydrogen atoms are able to permeate through the outside wall of the probe which induces a current. This current can then be translated to a PH level. Included below is an illustration of how the probe works and its spec sheet

The PH prob would usually be in the sample reservoir but I do not currently have water running through my system so the probe cap filled with a storage solution is attached to prevent the sensor from degrading

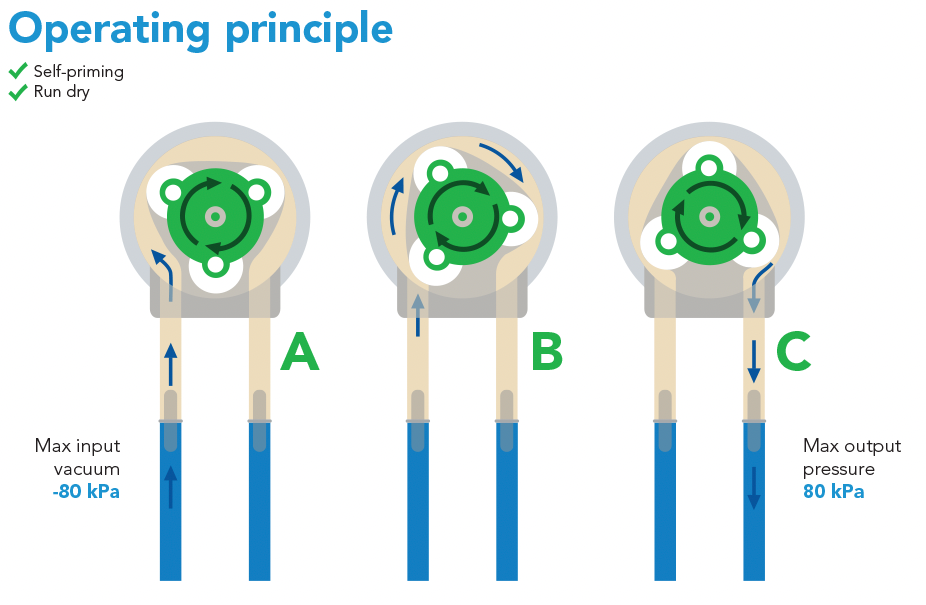

The Raspberry Pi takes a reading every 5 minutes. If the PH levels are not in the optimal range the Pi will send a signal to the peristaltic / dosing pump to add the appropriate buffering solution to the main reservoir. The process will continue until the PH returns to the optimal level

Peristaltic pumps use rollers to create positive displacement forcing fluid through the tube. The main advantage of this design is that the tubing is the only part of the pump that come in contact with the liquid being dispensed. This is ideal when using corrosive liquids such as strong acids or bases (ie the buffering solutions)

Nutrient Levels

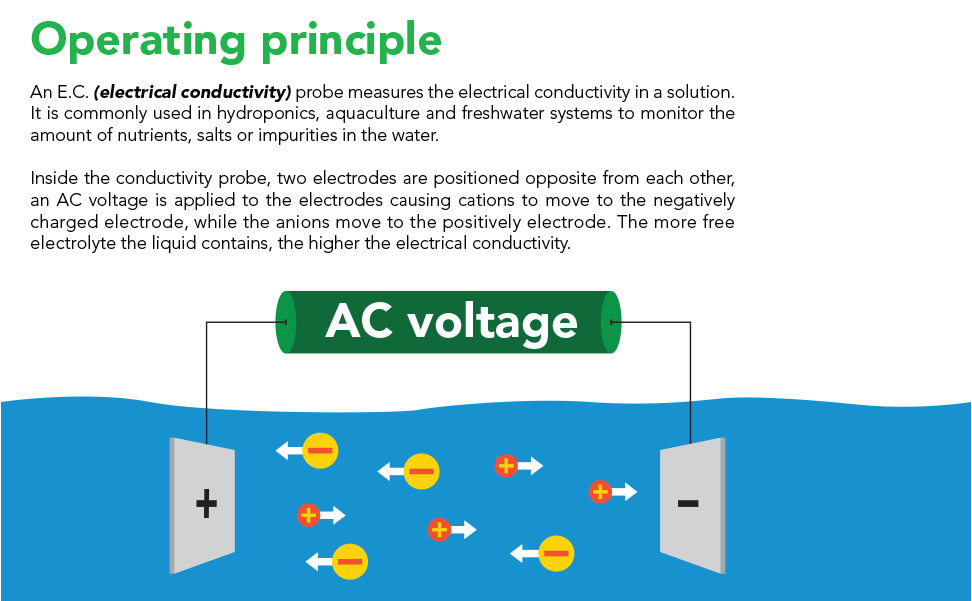

In a hydroponic system all the nutrient for the plant needs to be added through fertilizer. Pure water is actually not conductive. Water needs charged ions, usually in the form of dissolved salts to be able to pass a current. We use this property to our advantage by using distilled water which is close to pure water. Now when we add fertilizer (salt) to the water we can measure the concentration by the conductivity of the water. More fertilizer (salt) will make the water more conductive. This measure is called Electrical Conductivity or EC.

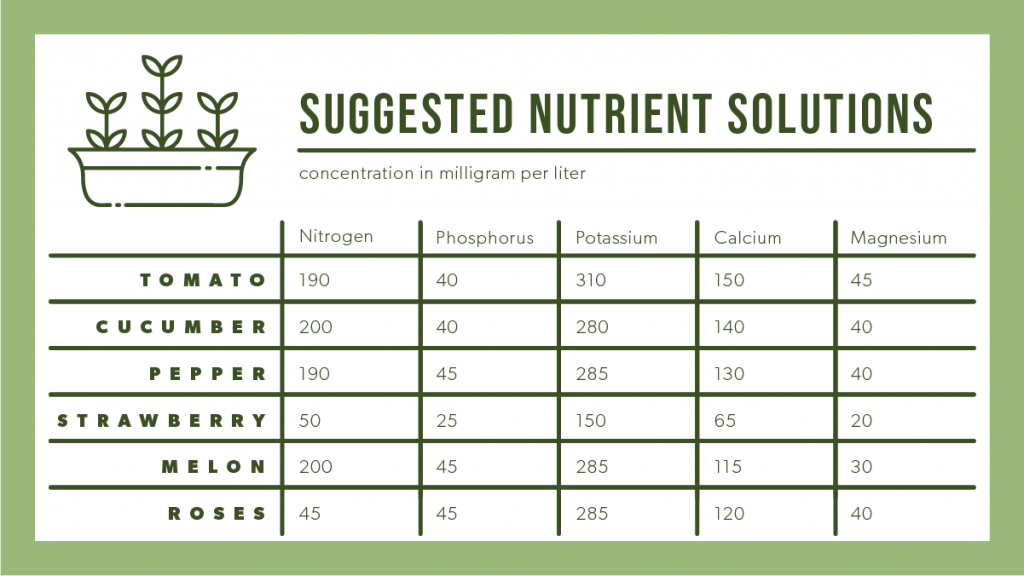

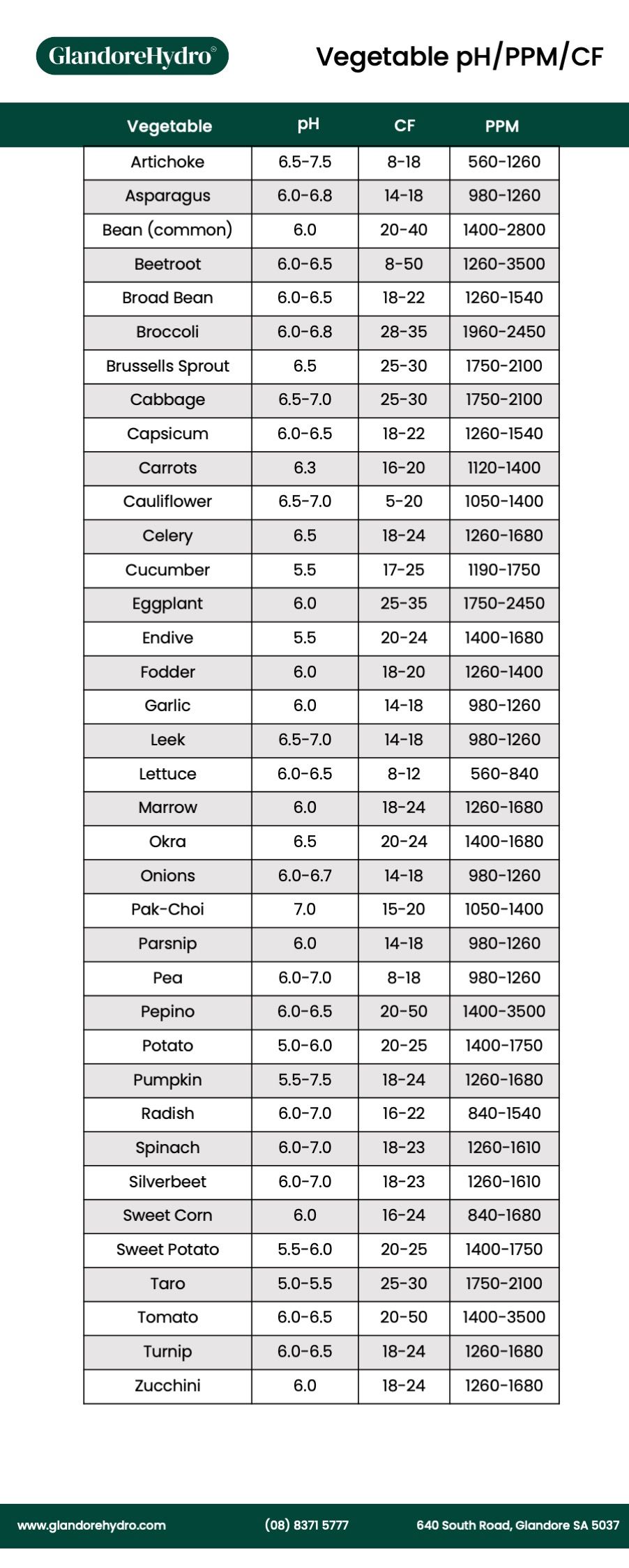

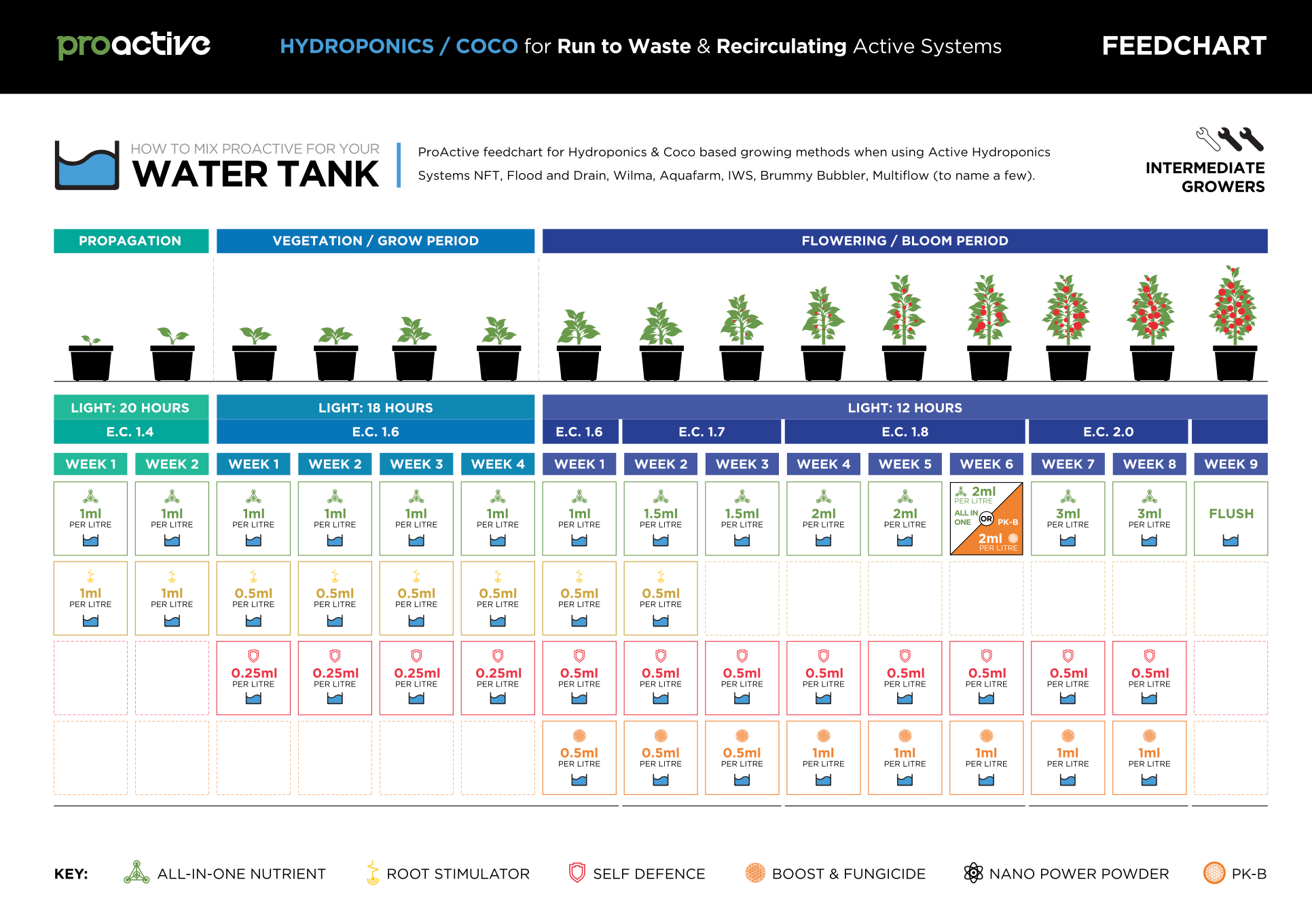

The optimal EC will vary by plant, stage of life, grow system, and vapor pressure deficit (VPD). The image below shows a basic EC guide for many common hydroponic vegetables

The nutrient needs of your plant will vary by the stage of life. This guide above is great for beginners or for plants who don't fruit such as lettuce but will leave results on the table for flowering plants. For flowering plants you will usually start low and slowly increase the EC levels until the flowering stage where the EC levels grow more quickly. About a week or two before harvest you will remove all the nutrients from the water in what is called a flush. Flushing the plants helps them to burn off any built up nutrients from the growth process improving the quality of the fruit.

The last factor effecting EC levels is the vapor pressure deficit. We will go into more detail later in this post but its effectively a measure of how much water the plant will lose to the environment. If the VPD increases the plant will need to draw more water from its roots. The more water the plant draws the lower the EC needs to be to prevent nutrient burn. Unlike PH there are a lot of factors that will effect the proper nutrient levels. Since there is no perfect guide it's important to know the signs for nutrient deficiency/toxicity.

It can be relatively hard to diagnose nutrient deficiency for plants growing in soil as each nutrient has a slightly different symptom. Luckily in hydroponic systems it is relatively easy. Most hydroponic fertilizers are complete nutrient solutions meaning we shouldn't be lacking any one nutrient. We previously talked about how the PH levels effect which nutrients can be absorb so that is the first thing to check if you are suspecting a deficiency. If the PH is in the correct range then the deficiency is usually characterized with slow growth and yellow leaves. If you are seeing this you will want to increase the EC of the water

Nutrient Toxicity also called nutrient burn is when plants build up a toxic amount of nutrients. The common symptom for nutrient burn is the browning at the edge of the plants leaves. If you see this you will want to lower the EC or the VPD. In severe cases you may want to do a flush to encourage the plant to burn off the excess nutrients built up.

In my setup, I use a continuous monitor EC probe connected to a Raspberry PI. The probe is contained in a sample reservoir. This gives any fertilizer added ample time to homogenized before it reaches the probe.

I program the optimal range of the EC to change according to the plant and growth stage. If the EC levels fall out of the optimal range two pumps will add a two part nutrient (A + B). The reason for the two part solution is because some of the elements that make up the fertilizer would react (usually with calcium creating calcium phosphate) and create sediment. By keeping these reactive elements separated we get two completely dissolved liquids.

Water Temperature

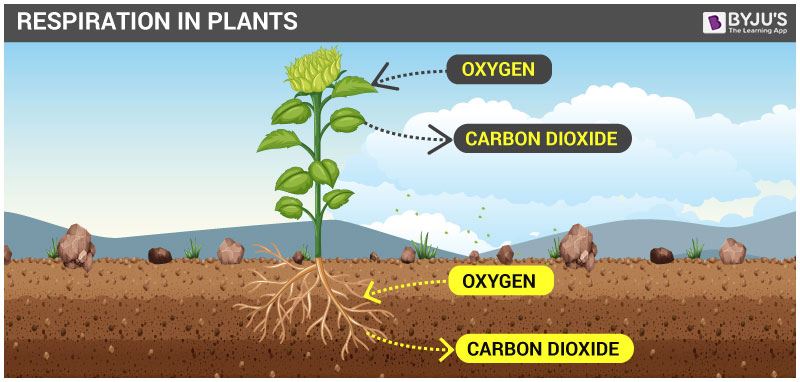

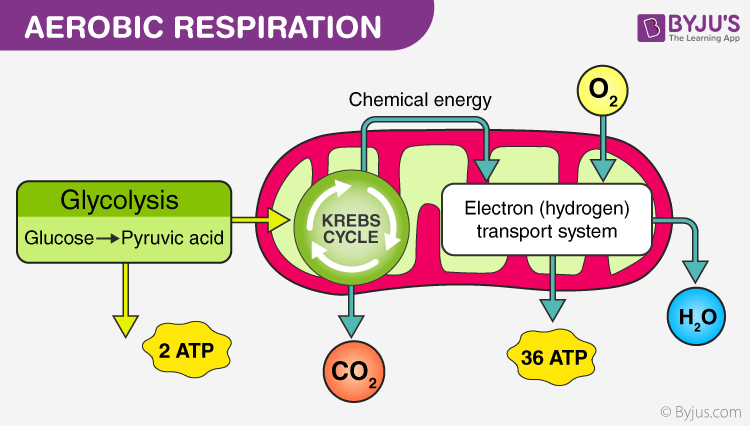

We all know that plants take in CO2 and produce oxygen during the photosynthesis process but it may surprise you that plants also need oxygen to survive. During the plants respiration cycle oxygen is used to break down carbohydrates into water and CO2

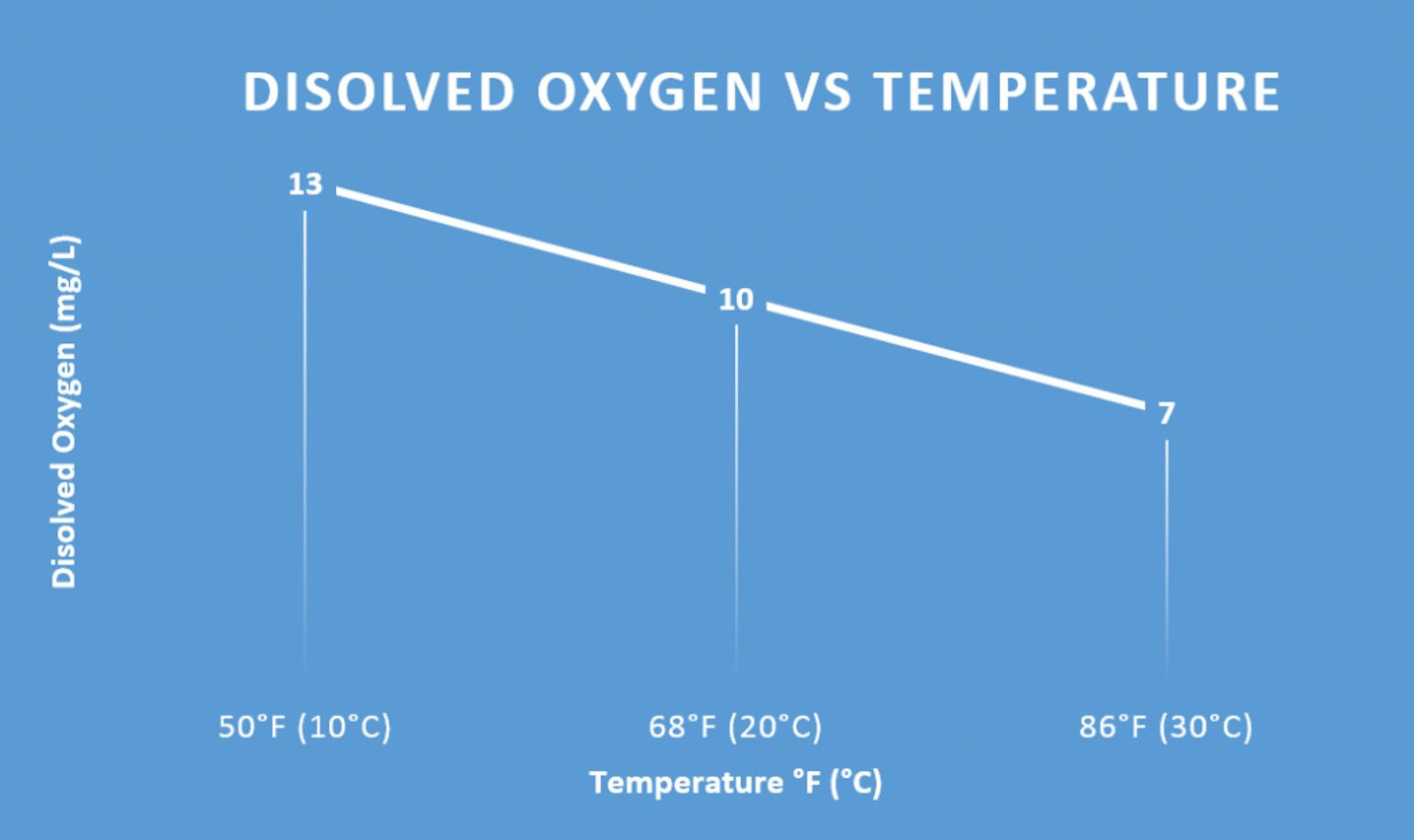

In order to make sure the plant roots have enough oxygen we need to maintain a cool water temperature. This is due to the fact the cold water can hold a larger amount of dissolved oxygen. From the graph below it may seem like the colder water the better, and that would be true except that the metabolic rate of the plant decreases with temperature. Because of this inverse relationship, there is a balance between having the right amount of oxygen and plant growth.

Another important factor in controlling the water temperature is preventing harmful bacteria and fungus such as phytophthora megasperma (root rot) which propagates at higher temperatures (85F +). Root rot is a fungus that grows on the plants roots where it prevents the plant from absorbing nutrients. This will cause nutrient deficiency and can eventually kill the plant. The infected plant will look wilted, the leaves will yellow, the growth will be stunted, and the roots will be brown and slimy

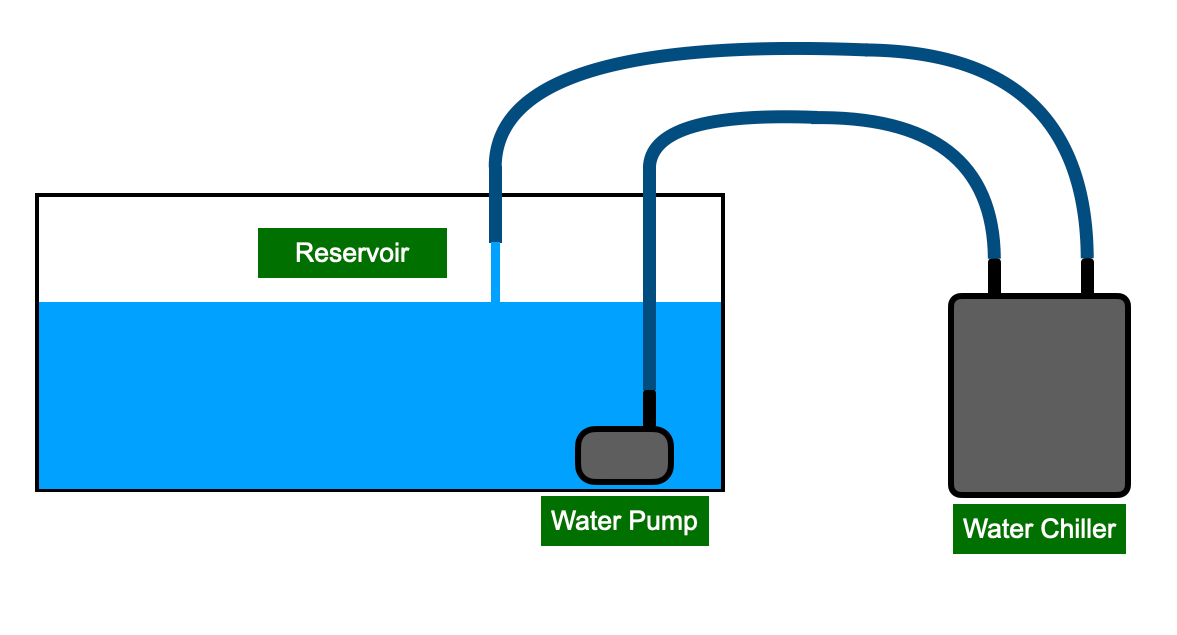

In my setup I use a water chiller to control the water temperature. Inside the reservoir a submergible water pump flows water through the water chiller where the water is cooler and then returned to the tank

The water chiller can be set to a temperature and will turn on and off to maintain the temperature range. 67F - 70F is generally the optimal temperature, but it can very plant to plant. If you are interested in the optimal range for a specify plant there are a ton of studies such as this one on lettuce https://file.scirp.org/pdf/AJPS_2015091616560642.pdf

Water Oxygen Levels

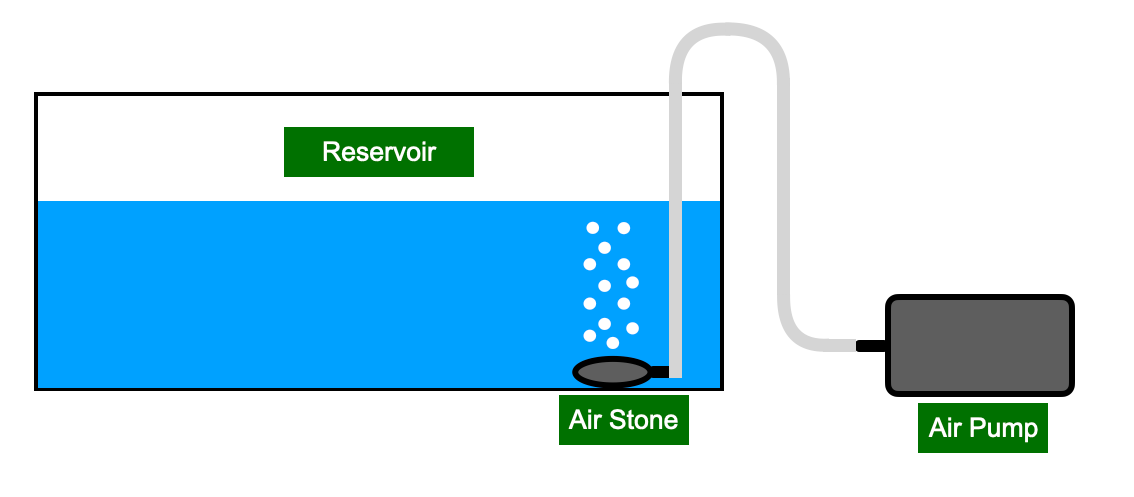

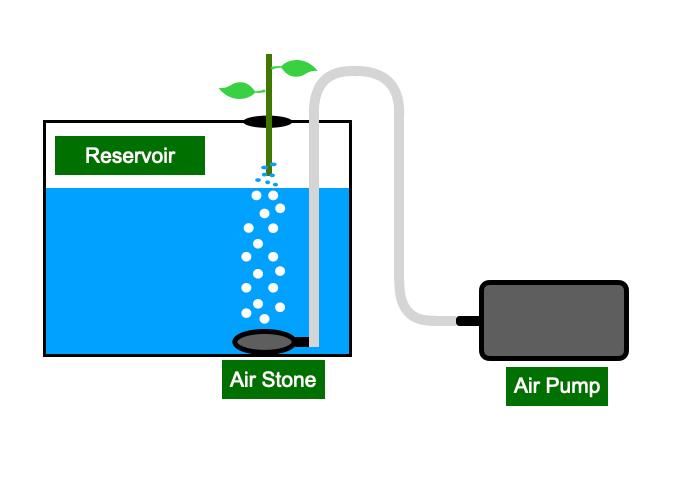

As plants take oxygen out of the water to preform respiration it is important for us to replace it. In a hydroponic system this is done using an airstone.

In my hydroponic setup an air pump pushes air to an airstone which acts as a diffuser and separates the air into many tiny bubbles. Theses tiny bubbles increase the contact area between the air and the water. Some of the O2 molecules from the bubbles are then absorbed by the water, increasing the amount of dissolved oxygen. I use an 8" airstone connected to a 32W airpump. This is enough to keep the water in my reservoir fully saturated at 10mg/L

Photosynthetically Active Radiation (PAR)

During photosynthesis, plants take in water, carbon dioxide, and sunlight and produce oxygen and glucose (C6H12O6).

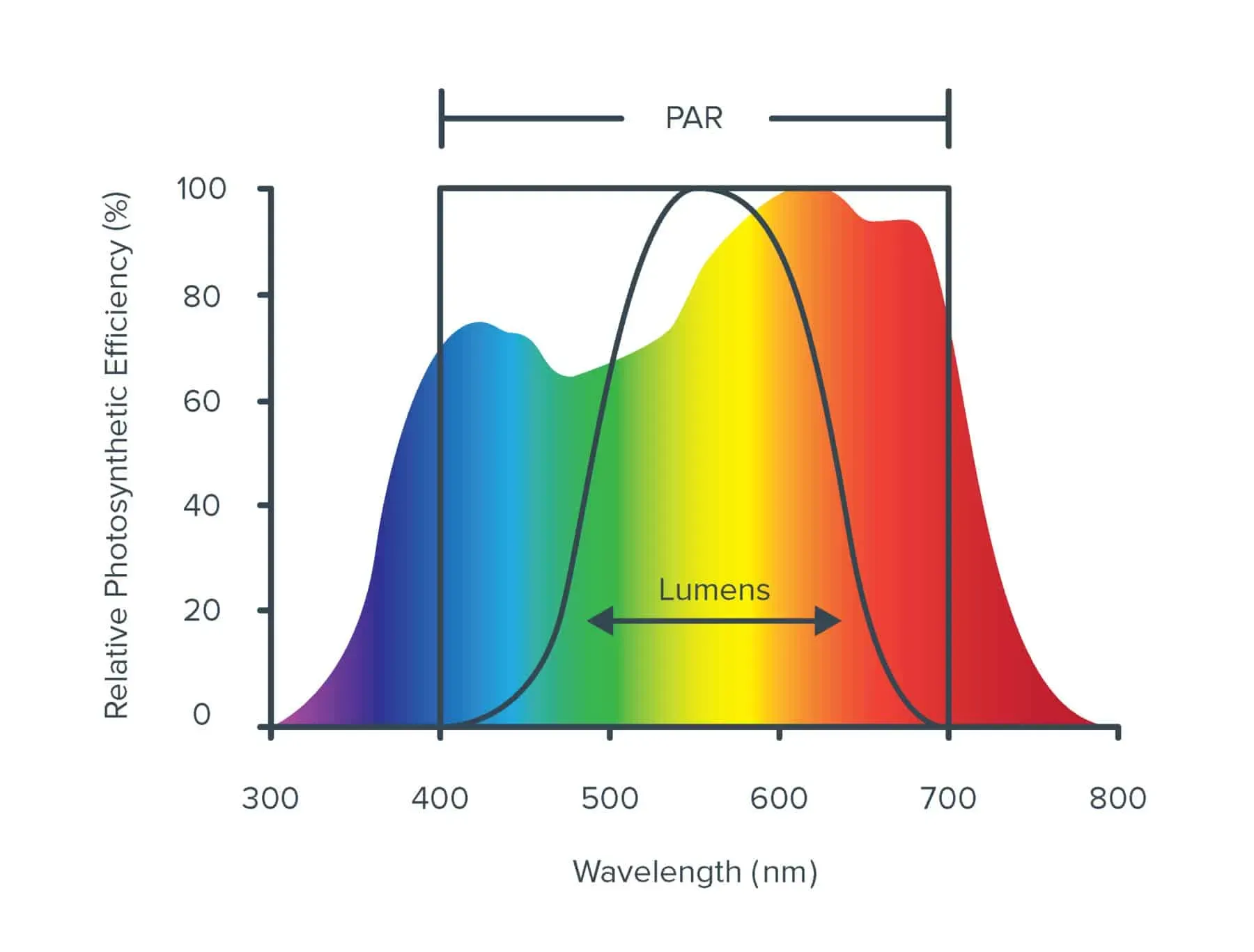

PAR or Photosynthetically Active Radiation is the waveband of light that plants are able to use during photosynthesis.

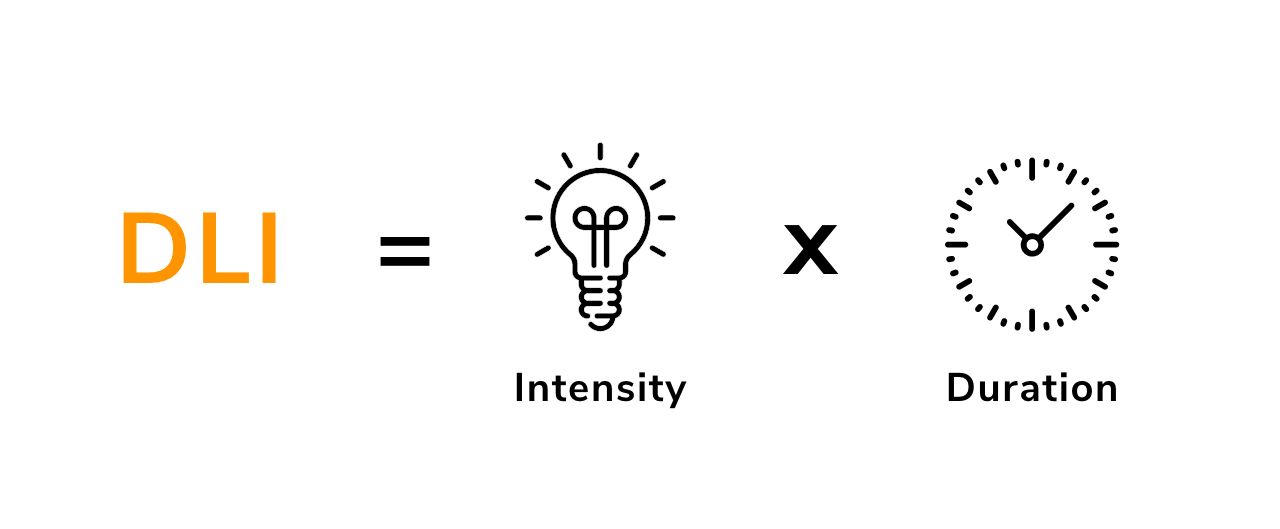

The intensity of light in this waveband is PPFD or Photosynthetic Photon Flux Density and is measured in umol/m2/s. The DLI or Daily Light Integral is the measure of this intensity over a 24hr period or mol/(M2 * d)

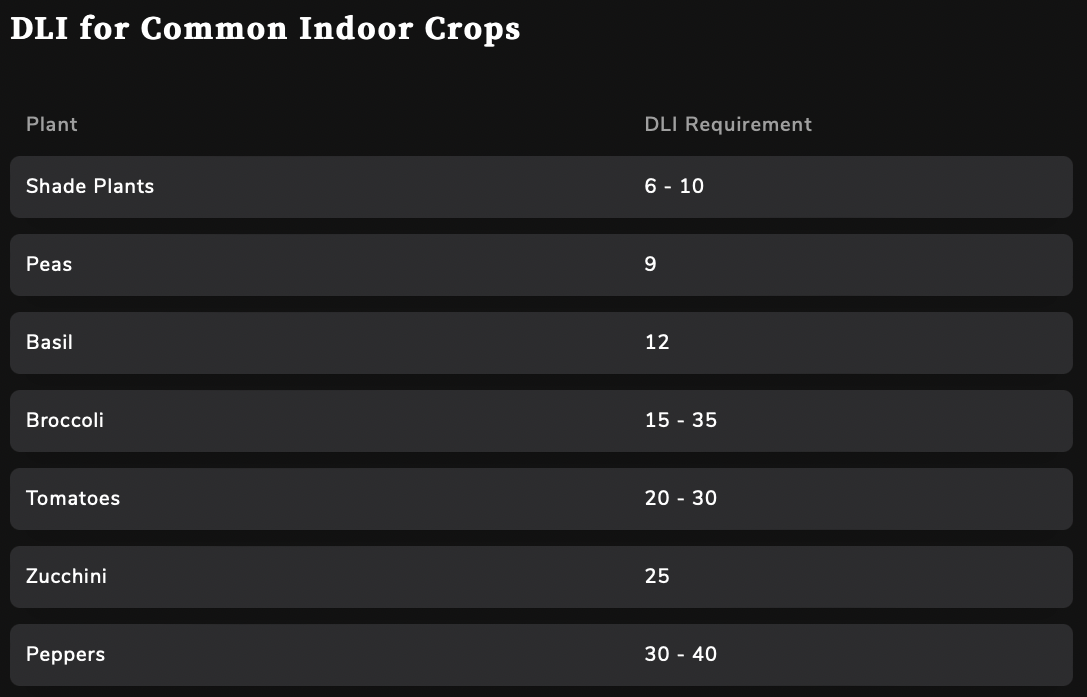

Different plants can vary wildly in the required DLI

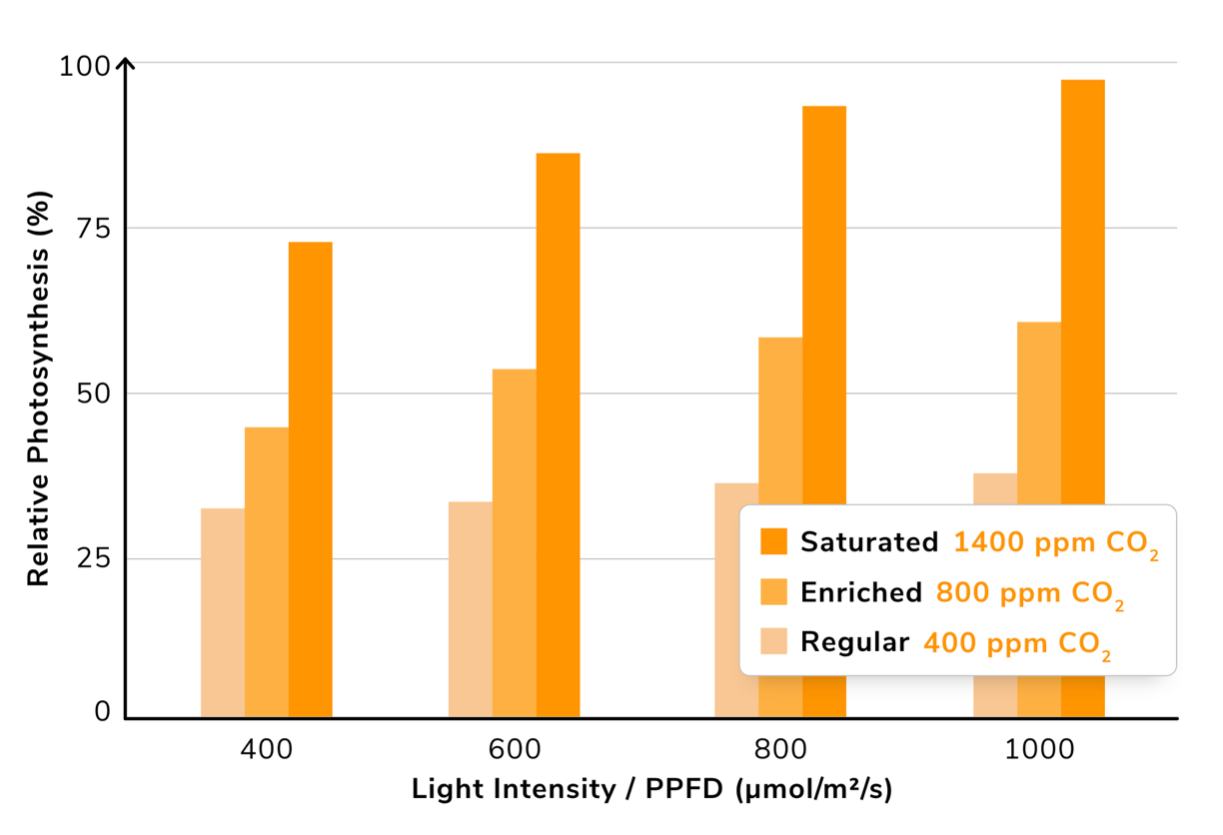

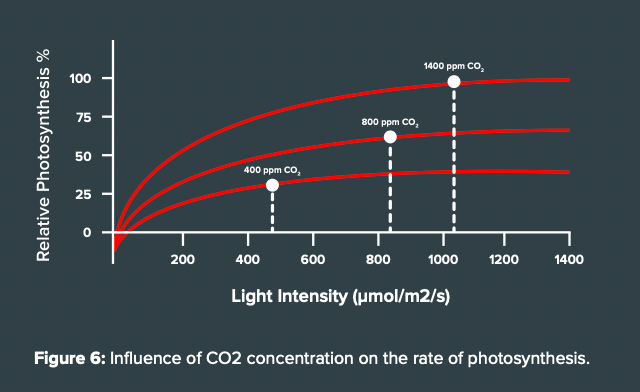

Within each plant the optimal DLI will vary with CO2 levels and stage of life. Below you can see without added CO2 the relative photosynthesis barely increases between 400 and 1000 PPFD. Referring back the photosynthetic equation CO2, water, and sunlight are all needed to create glucose. (6H2O + CO2 + Sunlight => C6H12O6 + 6O2). Because both CO2 and sunlight are require if levels of either are too low it will limit the growth

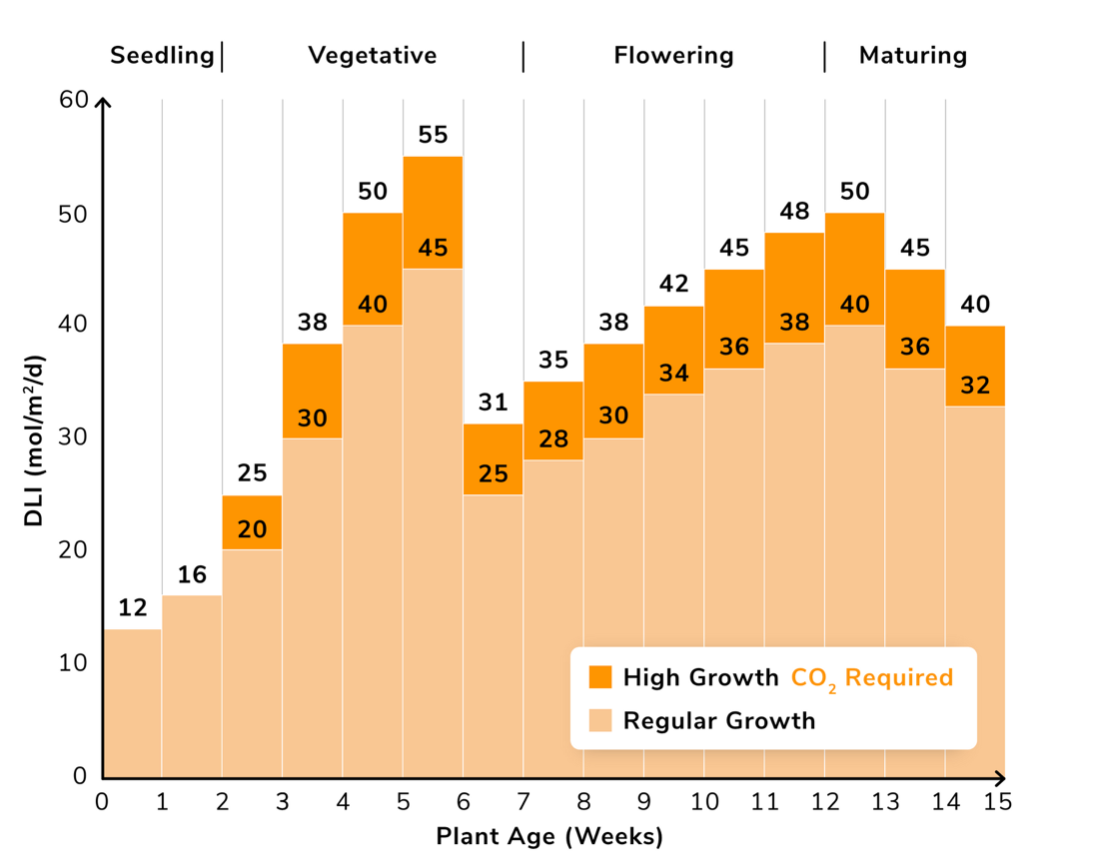

Much like the EC level, plants start with a lower level of PPFD and grow in intensity as they age. The chart shows a drop in the final week of vegetative. This is because some plants won't fruit without you simulating shorter day. This is usually done by shortening a 18hr light cycle to 12hr. If you remember the DLI equation is Intensity * Duration. This means that the decrease in DLI is due to the shortened duration and not a drop in light intensity

In my setup I used 4 100 watt full spectrum LED lights

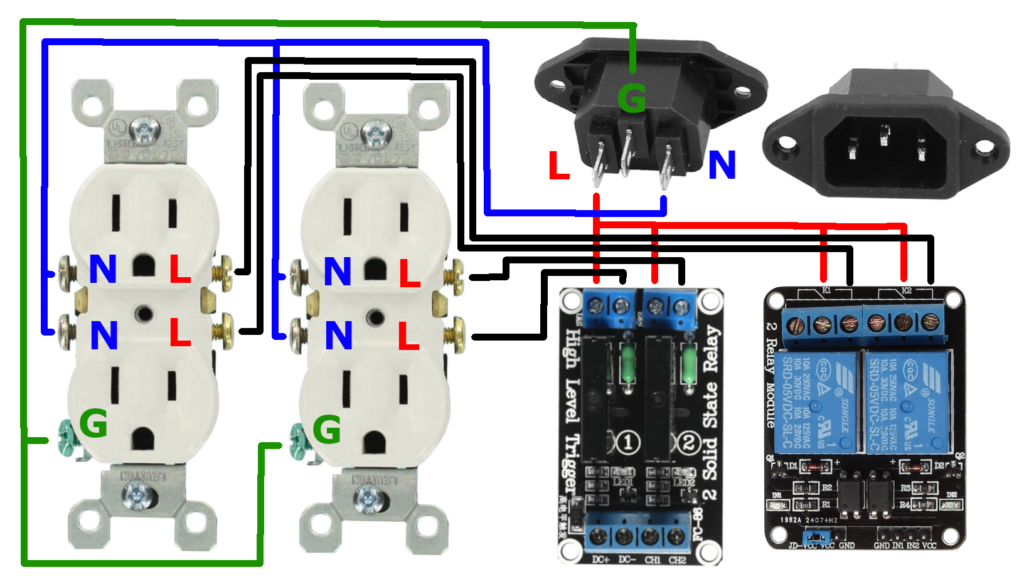

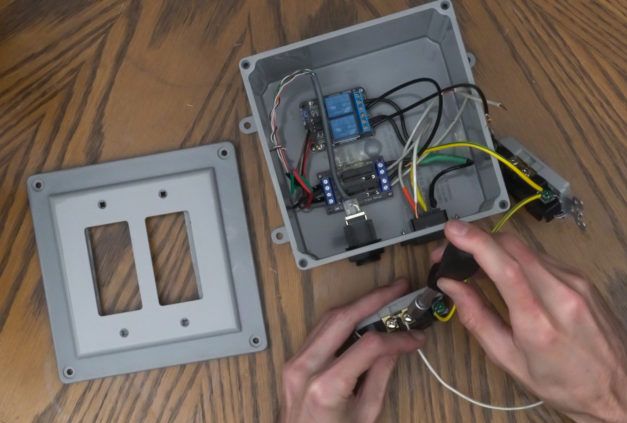

These lights are connected to a junction box controlled by relays

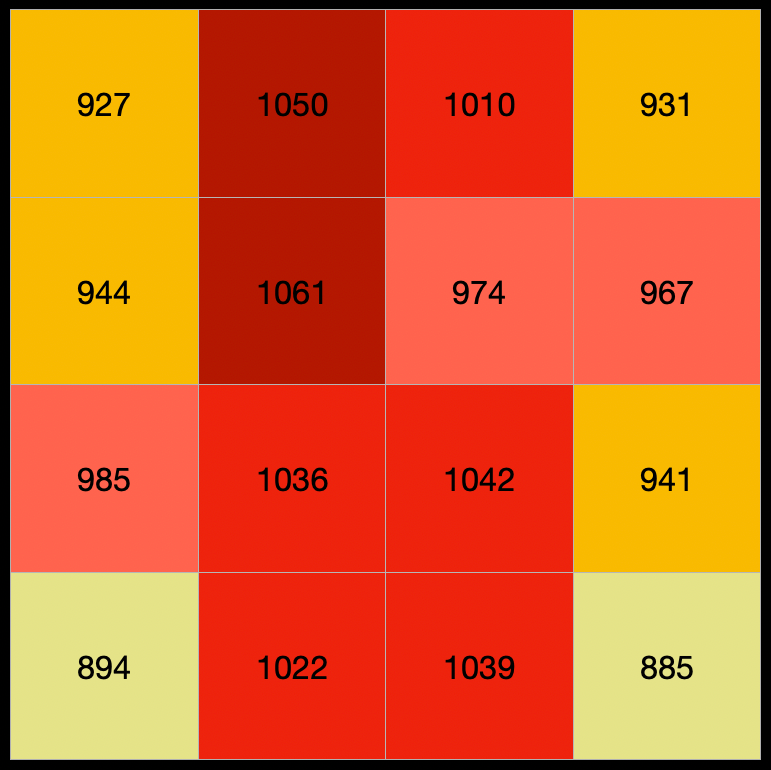

The schedule programed in the Raspberry PI sends signals to the relay to turn the lights on and off. I calculated around 1000 PPFD would give me the optimal DLI given I have around 1500ppm of CO2 in the tent. I then measured the PPFD in 16 locations and adjusted the light hight until I reached near optimal levels

Air Temperature

Plants have a species specific range of temperatures they will grow. Too low or too high and plant growth will stagnate. In between those temperature the plant will grow and in that range there is a CO2 dependent optimal. It's important to note that this relationship between temperature and photosynthesis is highly dependent of the PPFD in something called the photo-thermal quotient. PPFD will drive the production of glucose and the temperature will drive cell division. The ratio of the photo-thermalv quotient (PTQ) is calculated as PTR = DLI / T where DLI is the daily light integral and T is the temperature. The optimal ratio can vary but for most plants grown indoors it is <1

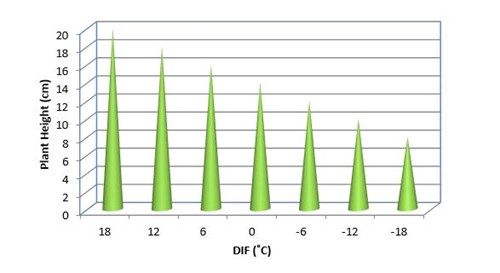

DIF or the difference in daytime vs nighttime temperatures also plays an important factor in plant development. Warmer day and cooler nights will promote stem elongation while cooler days and warmer nights will slow stem growth. This can be used instead of chemical plant growth regulators to slow plant stretching

In general you will want a DIF slightly > 0 when establishing the plant, ~10 during vegetation, and in between 5 and -5 during reproduction depending on your ability to accommodate future growth

In my tent temperature is measured with a temperature sensor position at the top of the plant canopy

If the temperature is out of range the Raspberry Pi will trigger the power control box to turn on the exhaust fan. Cold air from the outside of the tent will be pulled in and cool the air inside the tent. The lights emit a large amount of heat and act has small radiators so to increase the temperature the exhaust fan will simply not run

Vapor Pressure Deficate (VPD)

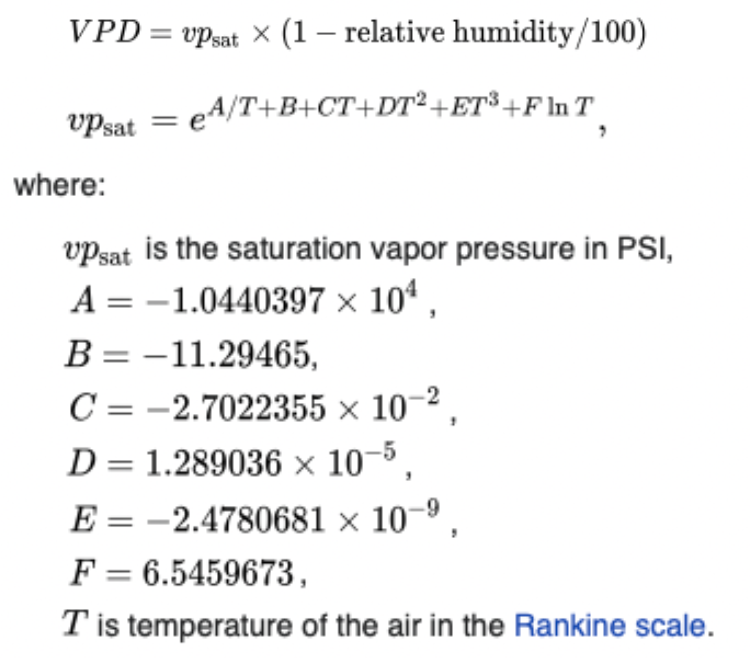

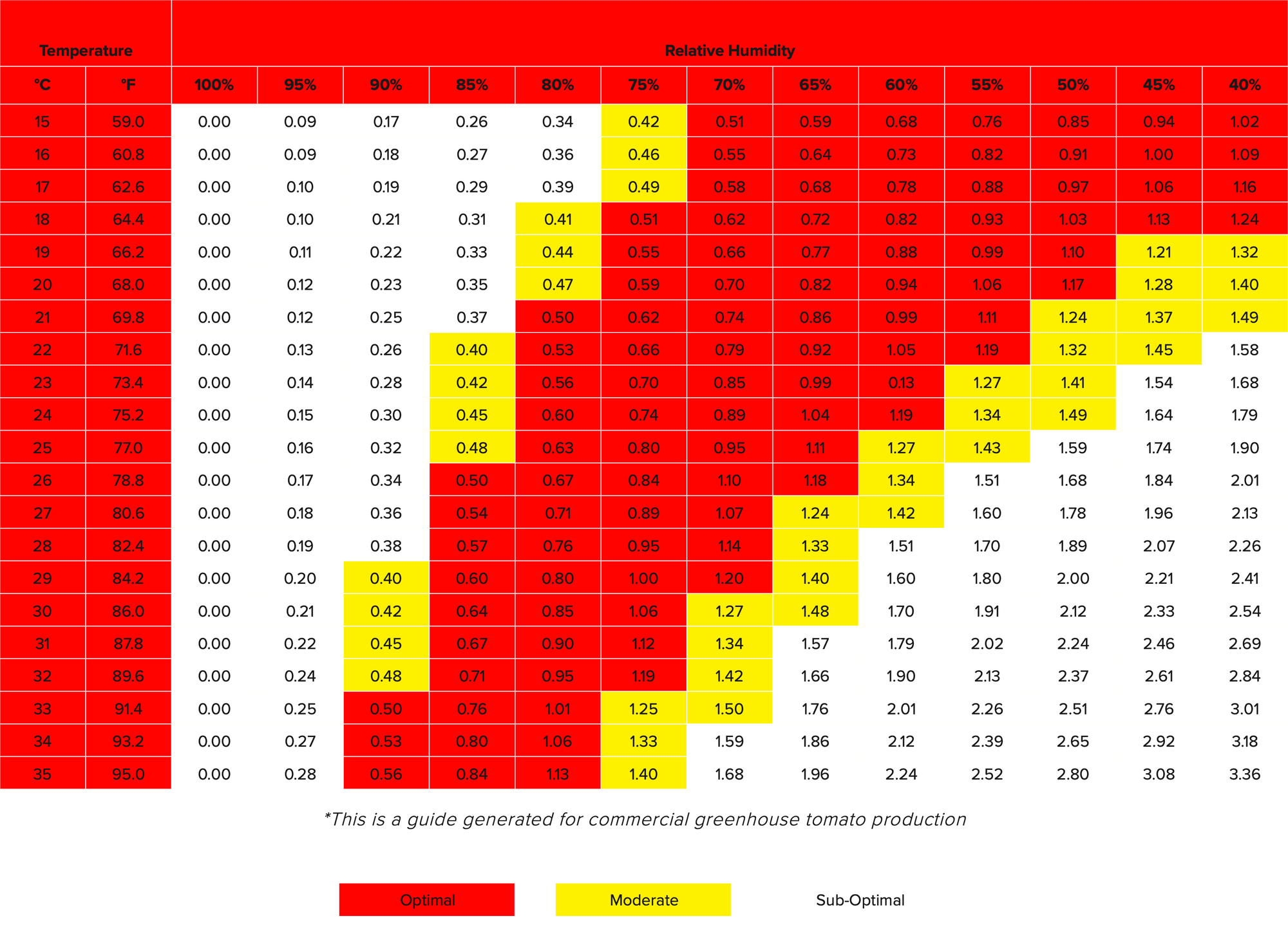

Vapor Pressure Deficit or VPD for short is expressed by a rather complicated equation but in simple terms in the difference in the vapor pressor of the leaf vs the vapor pressor of the air

Plants transport water through its roots and into its leaves in a process known as evapotranspiration. VPD is used to modulate the evapotranspiration. If the VPD is too low (High Humidity) evapotranspiration will be slow, the plant will not be able to bring in enough nutrients, and water will pool on the plant's leaves leading to mold and disease. If the VPD is too high (Low Humidity) evapotranspiration will quicken, the plants will absorb too much nutrients, and the plant will be stressed. The optimal range will vary by plant species but it generally falls between 0.5 - 1.3 kPa

In my setup the temperature sensor also measures VPD

The VPD is regulated through a control loop / PID controller (Proportional–Integral–Derivative controller). In short if the VPD is too low (High Humidity) the exhaust fan will turn on. The average humidity where I live is ~30% so the air outside the tent is enough to lower the humidity and a dehumidifier is not needed. If the VPD is too High (Low Humidity) then the power control box will turn on the humidifier until the humidity returns to the optimal range

CO2

Elevated levels of CO2 greatly boosts the growth potential of plants through increased rates of Photosynthesis

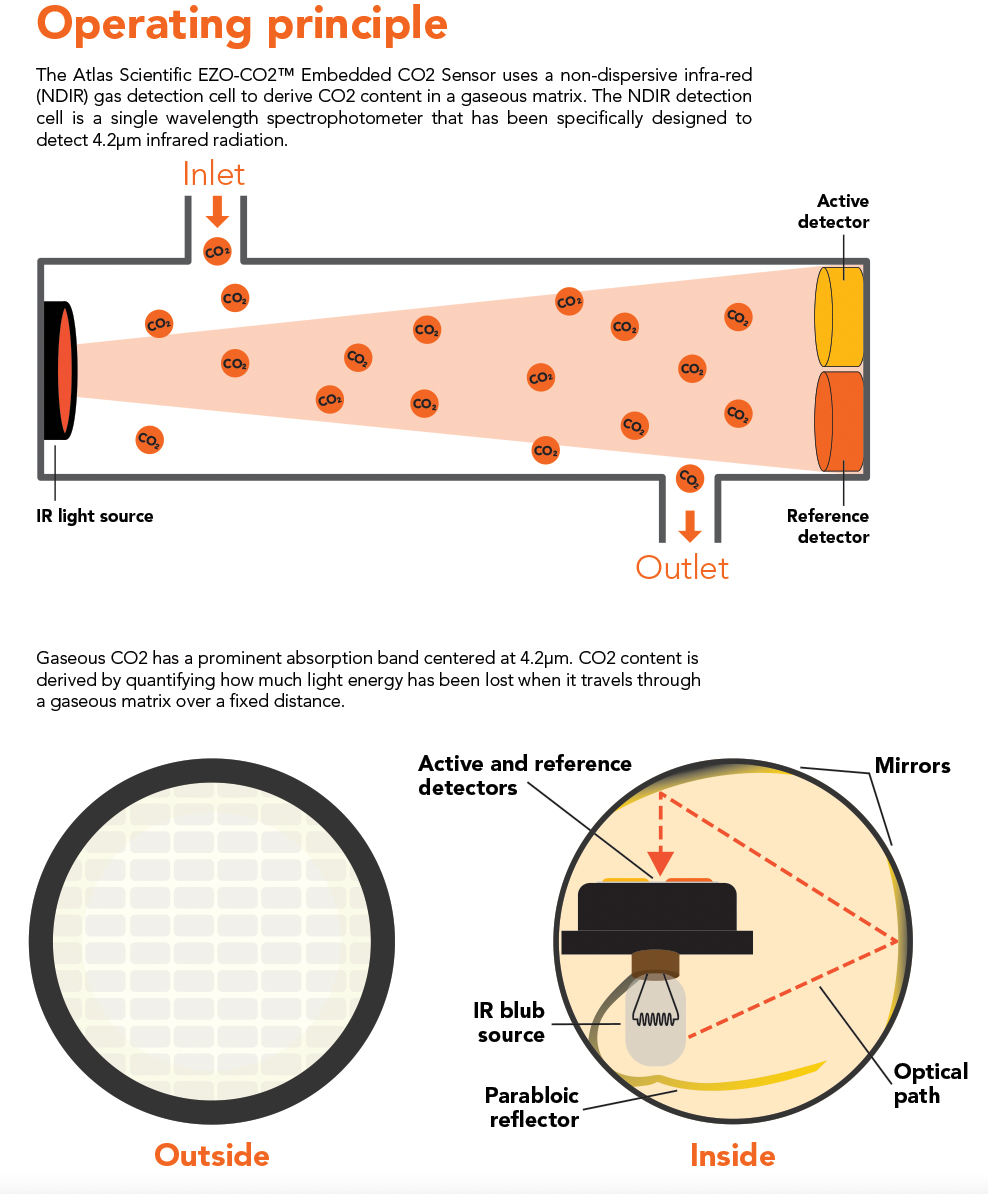

To maintain optimal CO2 levels of 1400PPM I used a CO2 sensor to monitors the carbon dioxide levels. CO2 sensors can be sensitive to light so the sensor is placed in a PVC T

If the CO2 levels fall out of range the power control box will open the solenoid in the CO2 regulator to allow the flow of CO2 from the tank to the tent

To disperse CO2 inside the tent a "shower" was created by drilling small holes in the airline hose and running the hose in rows above the plants

Finally a small fans in each corner provides airflow to break the boundary layer around a leaf and allow for the uptake of CO2

Genetics

Variation in the optimal environment is not limited to plants of different species but also within the species due to varying genetics. Striking /cloning is a form of asexual reproduction that can be used to eliminate this variation. A cutting is removed from a plant and placed in a growing medium. The cutting will eventually root and become a new, genetically identical plant. The major benefit of this grow style is that I can reuse the same genetics grow after grow. Since I can control every aspect of the growth environment, I will be able to fine tune the settings until I zero in on the perfect environment for the specific genetics of this plant. Once I find the optimal environment I should then be able to replicate the results indefinitely

There are various processes that can be used to clone plants. Since these plants will be growing in a hydroponic setup I decided to use a clone propagation tank so the plants wouldn't have to change growing mediums. Clone propagation tanks work by pumping air through an air stone. The airstone diffuses the water into many small bubbles that "pop" when they reach the surface. This agitation causes small amounts of water to reach the cutting. The cutting are constantly misted and will begin to root in 4-7 days

For more information on the clone propagation tank check out my post here: